Azul 3D lands $12.5M to advance proprietary printing tech

The funding will help Azul 3D launch its first commercial printers too

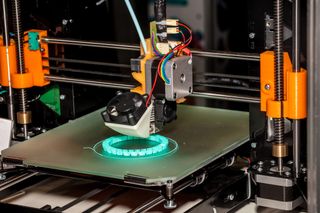

Azul 3D has secured $12.5 million in oversubscribed seed financing to advance its proprietary high-area rapid printing (HARP) technology and launch its first commercial printers.

Azul 3D unveiled its new 3D printing technique last fall when it announced a 13-foot-tall printer that boasted a 2.5-square-foot print bed capable of printing about half a yard in an hour. Ever since the announcement, the company has continued picking up steam.

Amid the coronavirus pandemic, Azul 3D has used its HARP technology to produce medical face shields at a record rate of 1,000 components per printer in a 12-hour shift. The company plans to accelerate its beta printers to print 20,000 shields per week within the next few months.

“One of the reasons we’re doing so well is because our technology offers a solution to unexpected surges in demand and supply-chain bottlenecks that occur during global crises, such as in the current pandemic,” said David Walker, Azul 3D co-founder and chief technology officer.

“With the ability to manufacture nearly anything quickly and on demand, we can meet these unexpected needs as they arise to quickly fill gaps in the supply chain,” Walker continued.

Chad Mirkin, Azul 3D co-founder and chair added, “Investors recognize the paradigm shifting and disruptive nature of Azul’s proprietary HARP 3D printing technology.”

Invented and developed at Northwestern University, HARP enables users to print 3D structures from various materials. The company says its HARP printers can manufacture parts at production speeds that outpace their competitors.

Get the ITPro. daily newsletter

Receive our latest news, industry updates, featured resources and more. Sign up today to receive our FREE report on AI cyber crime & security - newly updated for 2024.

As part of the funding round, Azul 3D also added several new key backers to its investor pool, including Louis A. Simpson, former Geico CIO, former manager of Berkshire Hathaway and founder of SQ Advisors; Wally Loewenbaum, former chairperson of 3D Systems; Joe Allison, former CEO of Stratasys Direct Manufacturing; and Hugh Evans, former senior vice president of corporate development for 3D Systems.